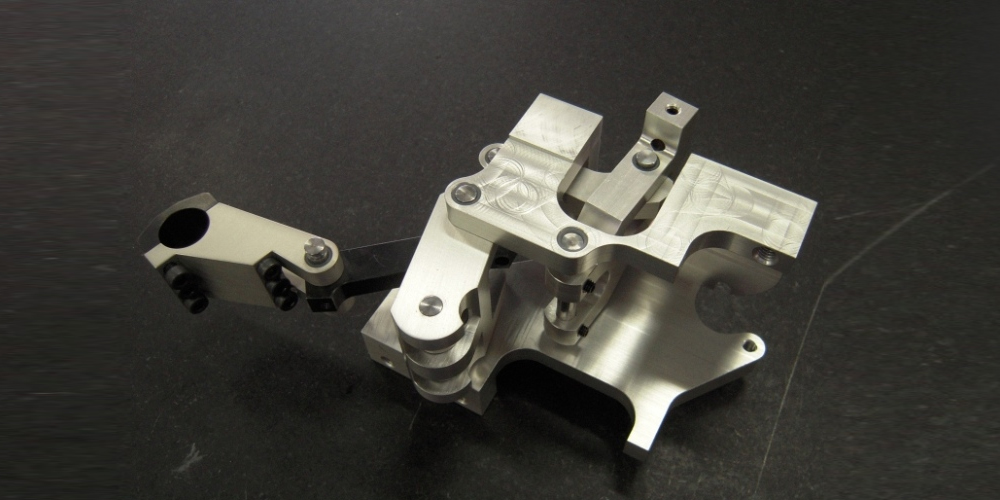

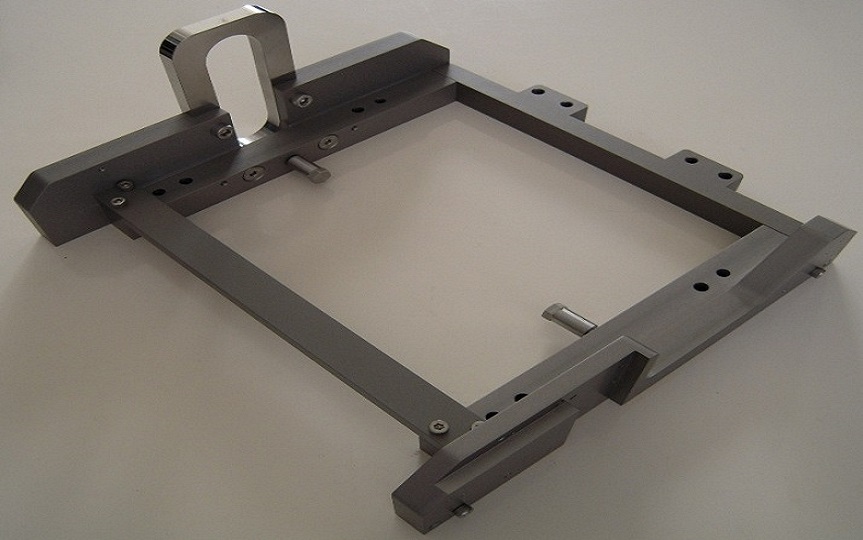

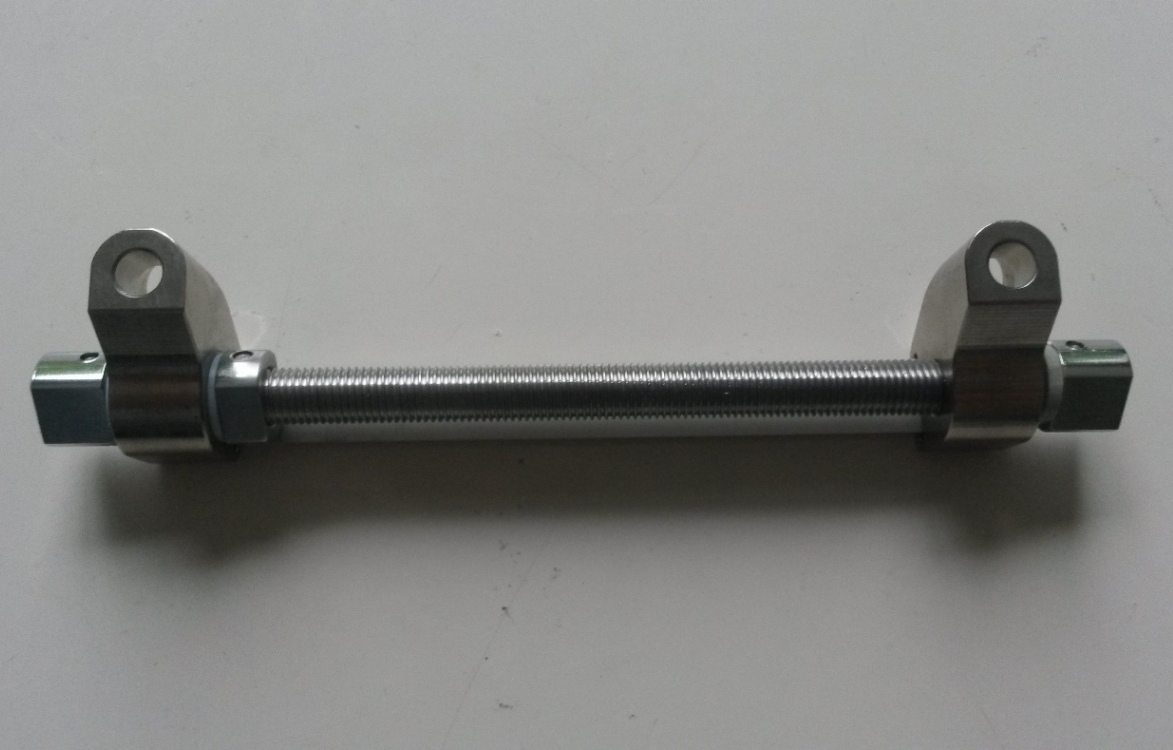

Outsourcing by OPS fits seamlessly with the needs of our target group; sub-contractors and OEMs in the small and medium size machine industries. Especially companies who are responsible for the functionality of assemblies, machines and modules for direct use.

OPS is supplier of fine mechanical precision parts, tooling and mechanical assemblies. We outsource the production of customer specified products in Malaysia. We Select the right manufacturer from our strictly selected supplier base, classified per product group. Our delivery is short irrespective of order size since we have multiple manufacturers per product group to meet the customer’s demand. That is why our supplier base is extensive.

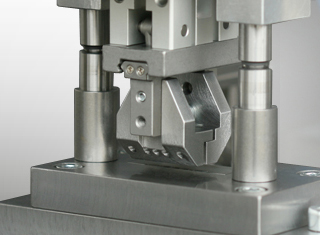

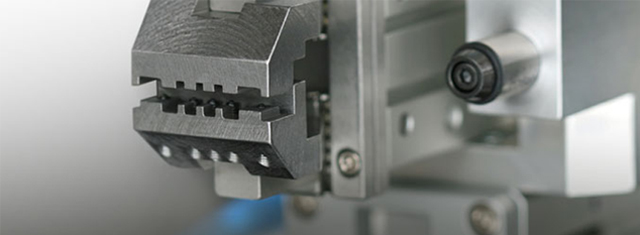

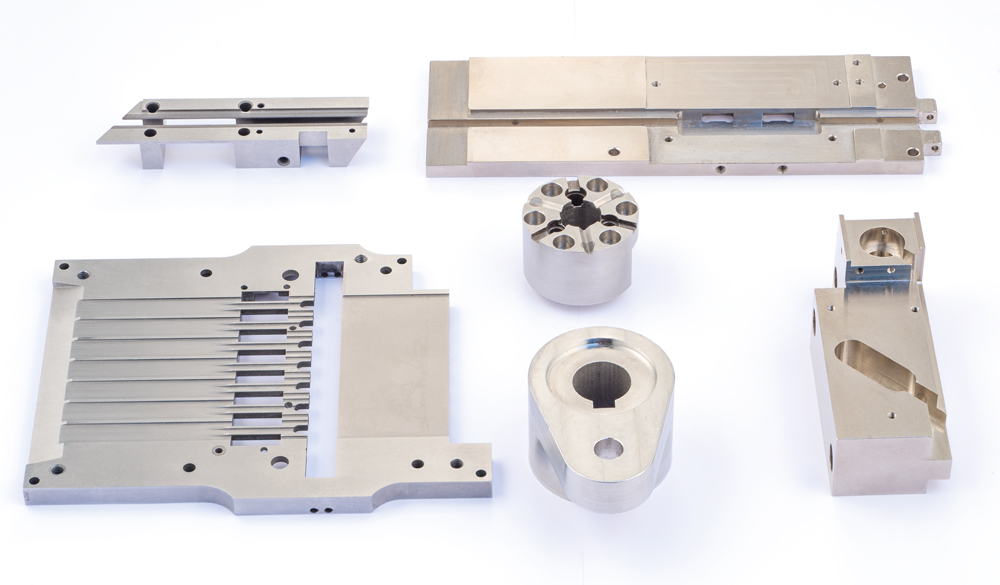

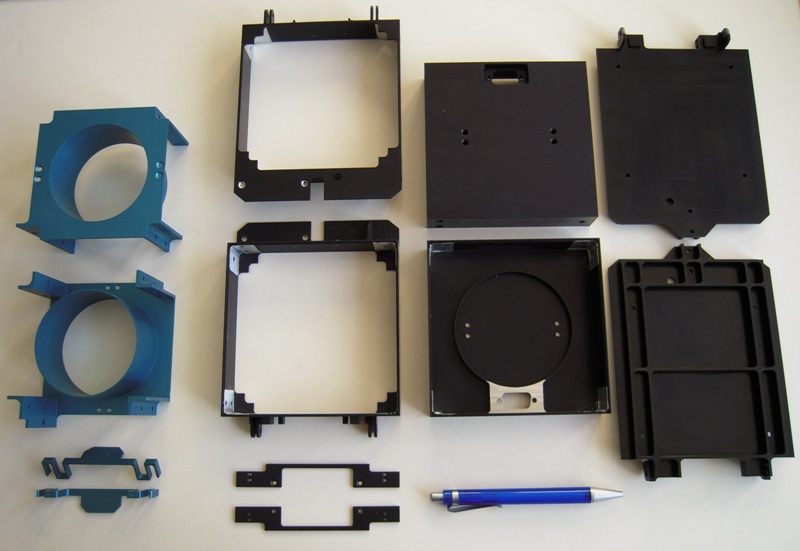

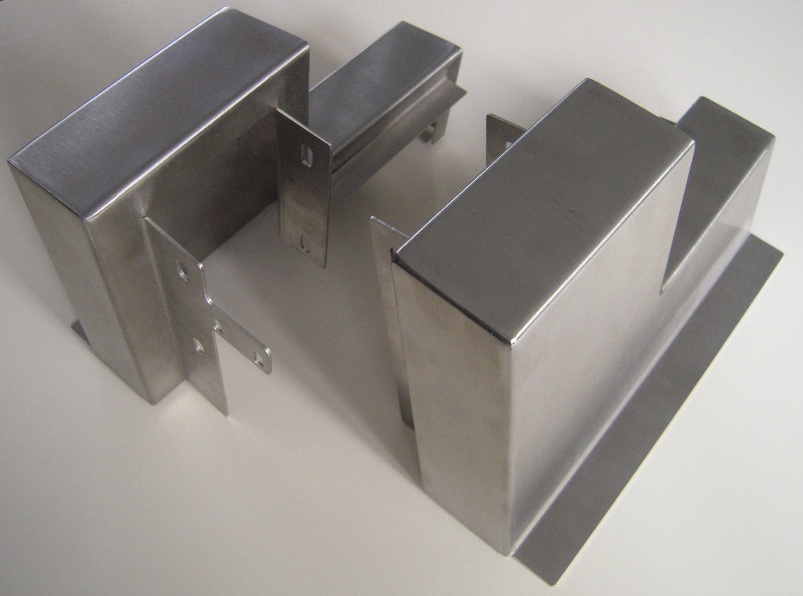

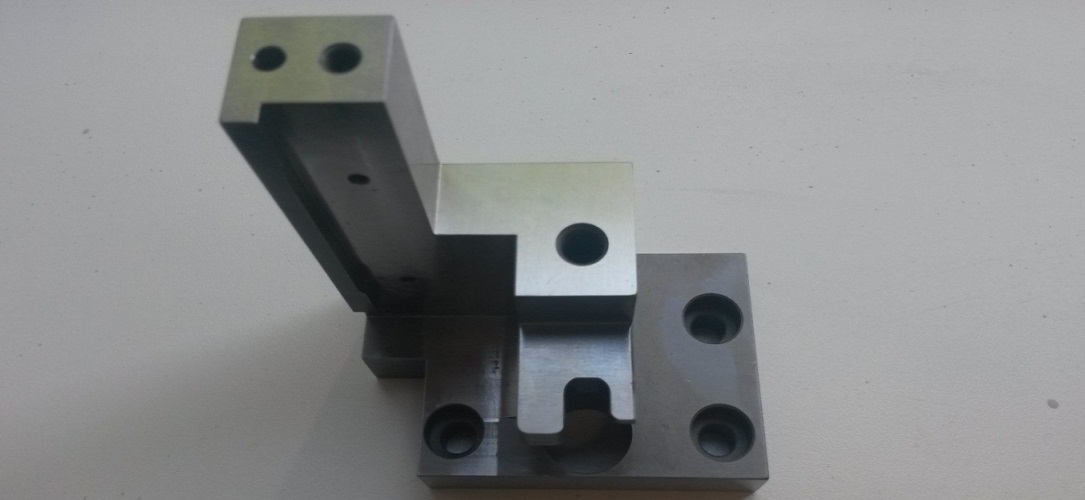

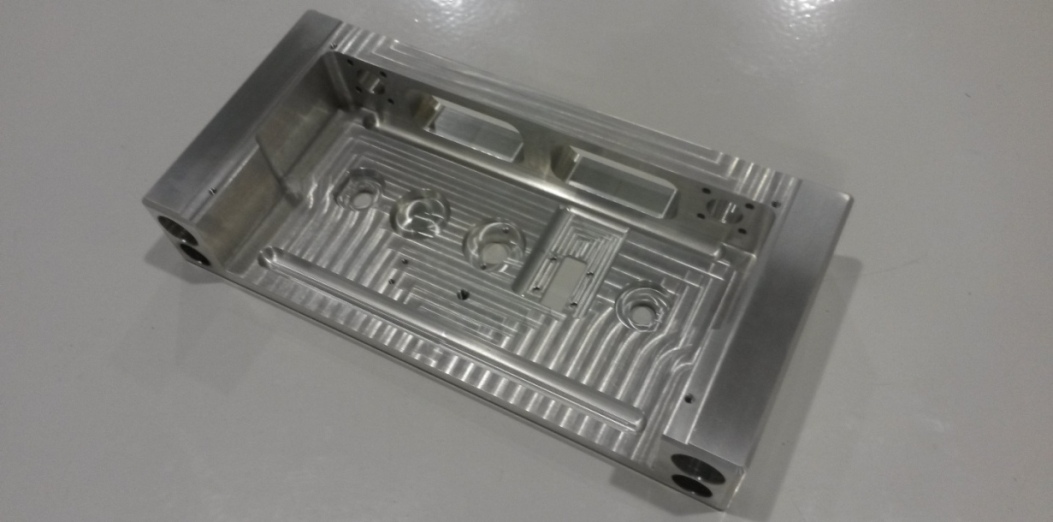

(CNC) turning and milling • (CNC) surface grinding and cylindrical grinding • Electrical discharge machining (EDM) • Wire sparking • Laser engraving • Welding (TIG, MIG/MAG, laser) • Surface treatments

By consolidating of orders, is our logistics efficient. This means a huge synergy advantage.

We work with various manufacturers in Malaysia. We strive for overcapacity and maximum flexibility in the supply chains. Our customers outsource accurate products to us. That is why we work together with manufacturers who have experience in the high-quality manufacturing industry. All products have a 100% quality control with a quality control report and/or a CMM report!

By achieving synergy in the outsourcing and logistics, we make outsourcing to Malaysia as lower cost country for small quantities per order line interested. OPS average lead time is 3.5 weeks. Maximum 5 weeks irrespective of the number of order lines. For example: 50 drawings will be sourced out to several identical manufacturers to achieve the desired delivery time of 5 weeks.

Due to demand-driven production and customer-specific requirements for machines and equipment, our customers need single items up to small numbers per order line. By creating economies of scale in outsourcing and logistics we enable outsourcing for small numbers per order line to 'lower-cost-country' Malaysia.

Our customers often produce to order and wish to have the products at the desired delivery times. OPS realizes delivery times from an average of 3.5 weeks to a maximum of 5 weeks, regardless of the number of order lines. We use several equivalent manufacturers to meet the delivery time at the same time.

Reduce your purchasing costs and management burden. We combine orders and the purchasing costs per product are lower for small quantities per order line combined with short delivery. Less orders less time in order processing, less receipts and less invoices. Due to larger purchase orders you reduce the integral costs of outsourcing.

The products that we outsource for our customers are divided into various product groups from regular to high-quality work. For these article groups we have a classified file from manufacturers.

Within the CNC turning and milling processes, wire and zinc sparks, grinding operations and construction sheet metal, we have selected various article groups with matching manufacturers.

Surface treatments, polishing work and the engraving of your features in the parts is possible.

| CNC Milling | 1000x600mm |

| CNC Lathe | Dia250x300mm |

| Lathe | 660x1000mm |

| Grinding | 400x600mm |

| Wirecut | 600x400mm |

| CNC Milling | 0.010 |

| CNC Lathe | 0.010 |

| Lathe | 0.025 |

| Wirecut | 0.005 |

| Grinding | 0.005 |

| Wire sparks | 0.002-0.005 |

| Surface grinding | 0.002 |

OPS started in 2007 by outsourcing and supplying Twan Smeulders. After his training in technical business administration, he held technical procurement and logistics positions at various OEM multinationals in the machine building industry.

OPS Synergy Malaysia was established in 2013. With the arrival of this 2nd office we can collaborate even more intensively with our manufacturers. William Tan Kee Sing is responsible as executive director of OPS Synergy Malaysia Sdn Bhd. He also has extensive experience in setting up and maintaining supply chains for High Tech Machinery. Because he has also worked for internationally oriented OEM multinationals, this enables him to understand the needs and expectations of our customers.

OPS works for companies that develop machines and subsequently want to outsource the manufacture of parts and individual assemblies.

We are a supplier of customer-specific single and composite precision engineering products. We outsource to our manufacturers in Malaysia with whom we have intensive daily cooperation. We only work with companies that have gained experience and have already proven their services. The production progress of all projects is discussed and monitored daily by the manufacturers. OPS customers acknowledge high delivery reliability.

We outsource your products to the right manufacturers and deliver them under our responsibility. We create scale benefits for you. No long delivery times, but low cost prices.